Time:2019.04.17 09:42 View: Anthor:admin

BackFirst, the development of central air conditioning

The central air-conditioning system is extremely common in modern enterprise and living environment improvement, and it is necessary in a living environment or production process. The so-called artificial environment is not only the temperature requirement, but also the humidity and cleanliness. So far, the central air-conditioning system is aimed at improving product quality, improving people's comfort, centralizing cooling and heating efficiency, managing, saving investment, etc. For this reason, almost enterprises, high-rise commercial buildings, business buildings, conference halls, theaters, Central air-conditioning is used in large-scale buildings such as offices, libraries, hotels, shopping malls, supermarkets, hotels, casinos, stadiums, etc. It is one of the indispensable supporting facilities for modern large-scale buildings. The consumption of electric energy is very large. Large consumers of electricity account for almost 50% of the electricity consumption, and the daily expenses are very large.

Because the central air conditioning system is designed according to the maximum load and a certain margin, in fact, in a year, the operation under full load is only more than ten days, even more than ten hours, and the load is almost 70% in most of the time. Run below. Usually, the load of the freezing main unit in the central air-conditioning system can automatically adjust the load according to the seasonal temperature change, but the refrigerating pump and the cooling pump matched with the freezing main machine can not automatically adjust the load, and operate under the load of 100% for a long time, resulting in the energy pole. The waste is also aggravating the operating environment and operating quality of the central air conditioner.

Second, The structure and working principle of the central air conditioning system

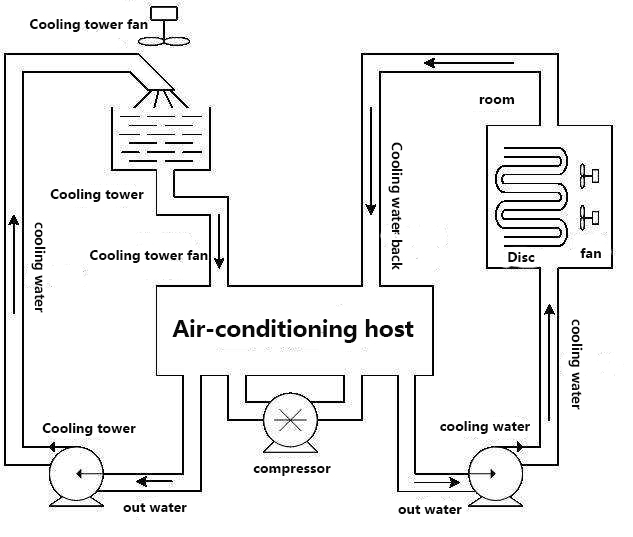

1.Refrigeration unit

The circulating water leading to each room is subjected to "internal heat exchange" via the refrigeration unit to cool the chilled water to 5 to 7 °C. An external heat exchange source is provided to each air conditioning point through the circulating water system. The heat generated by the internal heat exchange is discharged into the air through the cooling water system in the cooling tower. The internal heat exchange system is the "cooling source" of the central air conditioner.

2. Frozen water tower

Used to provide "cooling water" to the refrigeration unit.

3. "External heat exchange" system

This system consists of two circulating water systems:

a. The chilled water circulation system consists of a refrigerating pump and a freezing pipe.

The chilled water flowing out of the refrigeration unit is sent to the chilled water pipe by the refrigerating pump, and heat exchange is performed in each room to take away the heat in the room and reduce the temperature in the room;

b. The cooling water circulation system consists of a cooling pump, a cooling water pipe and a cooling tower. The heat exchange of the refrigeration unit will cause a large amount of heat to be released while the water temperature is being cooled. The heat is absorbed by the cooling water, causing the temperature of the cooling water to rise. The cooling pump presses the warm cooling water into the water tower to cool it. The tower exchanges heat with the atmosphere, and then sends the cooled cooling water back to the refrigeration unit, thus continuously circulating, taking away the heat released by the refrigeration unit.

4. Cooling fan

a. The indoor fan is installed in all rooms that need to be cooled, and is used to blow cold air cooled by chilled water into the room to accelerate heat exchange in the room.

b. The cooling tower fan is used to reduce the temperature of the water in the cooling tower and accelerate the heat brought back by the "return water" to the atmosphere.

The four parts of the central air conditioning system can be implemented with energy saving, but the power saving effect of the chiller and cooling water unit is the most ideal.

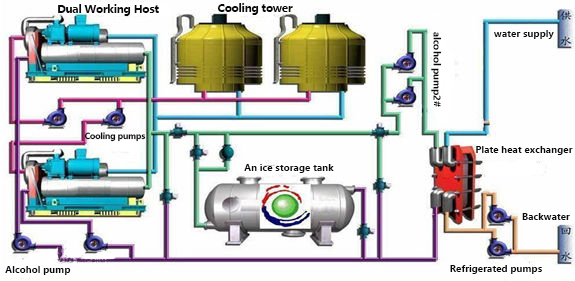

5. System composition

In the original system, the freezing and cooling water pumps are all Y-△ starting mode, and the starting current of the motor is 3~4 times of its rated current. Under such a large current impact, the service life of the contactor is greatly reduced; The mechanical impact at start-up and the water hammer phenomenon when the pump is stopped can easily cause damage to mechanical parts, bearings, valves and pipes, thereby increasing the maintenance workload and maintenance costs, and the equipment is also prone to aging.

In addition, since the cooling capacity of the refrigerating pump shaft cannot follow the change of the actual load of the system, the balance of the thermal working conditions can only be adjusted by manually adjusting the outlet temperature of the refrigerating main engine. As a result, a small temperature difference can be obtained by using a large flow rate. In this way, not only energy is wasted, but also the operating environment and operating quality of the system are deteriorated. Especially when the ambient temperature is low, some terminal equipment temperature control is slightly failure or the sensitivity is not high, it will cause the large-area air conditioner to be cold at room temperature, feel uncomfortable, and seriously interfere with the operation quality of the central air-conditioning system. The working principle of the fluid transmission equipment (pump, fan) shows that the flow rate (air volume) of the pump and the fan is proportional to its rotational speed; the pressure (head) of the pump and the fan is proportional to the square of the rotational speed; and the shaft power of the pump and the fan is equal to The product of flow and pressure, so the shaft power of the pump and fan is proportional to the cube of the speed (ie, the frequency of the power supply)

The third party is proportional to). The effect of energy saving of the frequency converter is very significant, and this energy saving return is visible. In particular, the system and equipment with large adjustment range and large starting current can be visually seen in Figure 2, as long as the flow rate changes, the pump shaft power will be changed to a greater extent as long as the speed (frequency) is slightly changed. The characteristics make the use of frequency converters for speed regulation become a trend, and continue to be deepened and applied to the field of speed regulation in various industries.

According to the above principle, it can be known that changing the rotational speed of the water pump and the fan can change the output power of the water pump and the fan.

Third, the frequency conversion transformation program

1. Reforming the refrigeration pump to the PLC The PLC controller reads the return water temperature and the outlet water temperature of the freezer into the controller memory through the temperature module and the temperature sensor, and calculates the temperature difference; then according to the temperature difference between the return water and the effluent of the freezer The value controls the speed of the inverter, regulates the flow of the water, and controls the speed of the heat exchange. The temperature difference is large, indicating that the indoor temperature is high and the system load is large. The speed of the refrigerating pump should be increased, the circulation speed of the chilled water should be increased, the flow rate should be increased, and the speed of heat exchange should be accelerated. If the temperature difference is small, the indoor temperature is low and the system load is small. Reduce the speed of the refrigerating pump, slow down the circulation speed of the chilled water, reduce the flow rate,

Reduce the speed of heat exchange to save energy.

2. Frequency conversion of the cooling pump When the refrigeration unit is running, the heat exchange capacity of the condenser is cooled by the cooling water to the cooling tower, and then sent to the condenser by the cooling pump for continuous circulation. The temperature difference between the cooling water inlet and the outlet water is large, indicating that the refrigeration machine has a large load, and the heat required to be taken away by the cooling water is large. The rotation speed of the cooling pump should be increased and the circulation amount of the cooling water should be increased; if the temperature difference is small, the refrigeration load is small and needs to be The small amount of heat taken away can reduce the rotation speed of the cooling pump and reduce the circulation amount of the cooling water to save electric energy.

3. Cooling tower fan frequency conversion control By detecting the temperature of the cooling tower water, the cooling tower fan is controlled by frequency conversion and speed control, so that the cooling tower water temperature is constant at the set temperature, which can effectively save the additional energy loss of the fan and achieve the best section. Electrical effect.

4. Inverter control of indoor fan unit By controlling the temperature of the cold room, the fan of the variable fan unit is controlled by the variable frequency speed control, so that the temperature of the cold room is constant at the set temperature. The indoor fan unit can achieve the ideal power saving effect after frequency conversion control, and the air conditioning effect is better.

Fourth, the advantages of the central air conditioning system for frequency conversion transformation

In addition to saving a lot of power, the frequency conversion energy-saving retrofit has the following advantages:

1) The motor starting is a soft start, the current changes from 0 A to the rated current, which reduces the impact of large current on the motor;

2) The motor soft start speed starts from 0 and slowly increases speed, which can effectively reduce the mechanical wear of the pump or fan;

3) The inverter is a high-performance power electronic device with strong motor protection function, which can extend the service life of all components of the system;

4) Keep the room temperature constant and make people feel comfortable;

5) After the transformation, the system can have higher reliability, reduce environmental noise and reduce maintenance and maintenance workload.

Address: 7F Bldg #E, North Area No. 8 Shangxue Technology Industrial city,Shenzhen,China

Company email: [email protected]

My WhatsApp: +86 13923476670

copyright ?深圳市瑋肯電氣技術(shù)有限公司 版權(quán)所有 粵ICP備13028075號-3

Web Map 丨